Contact

86-539-3101518

86-539-3101518

Fax: 86-539-3101518

Mobile: +86-15969943322

+86-18853986768

Official website: www.xrdplymachine.com

MIC website: http://xrdplymachine.en.made-in-china.com

Email: Jasonqiao@xrdplymachine.com

Factory address: No.1 Zhubao wood industry zone, Lanshan district, Linyi-276000, Shandong,China.

Office: F16, Amethyst mansion, Linyi, Shandong,China.

LOCATION:HOME > PRODUCTS > Boiler/Glue making plant > Boiler/Glue making plant

Biomass boiler

Date: 2020-01-09 15:47

View:

About us:

CHINA XINRUNDE COMPANY is a technology company serving the wood-based panel industry worldwide. Founded in 1989 year and located in worlds biggest wood-based panel production base -- LINYI City, which is famous for manufacturing all kinds of veneer, plywood, blockboard, particle board, LVL, MDF,HDF etc.. Thanks

Date: 2020-01-09 15:47

View:

About us:

CHINA XINRUNDE COMPANY is a technology company serving the wood-based panel industry worldwide. Founded in 1989 year and located in worlds biggest wood-based panel production base -- LINYI City, which is famous for manufacturing all kinds of veneer, plywood, blockboard, particle board, LVL, MDF,HDF etc.. Thanks

Detailed introduction

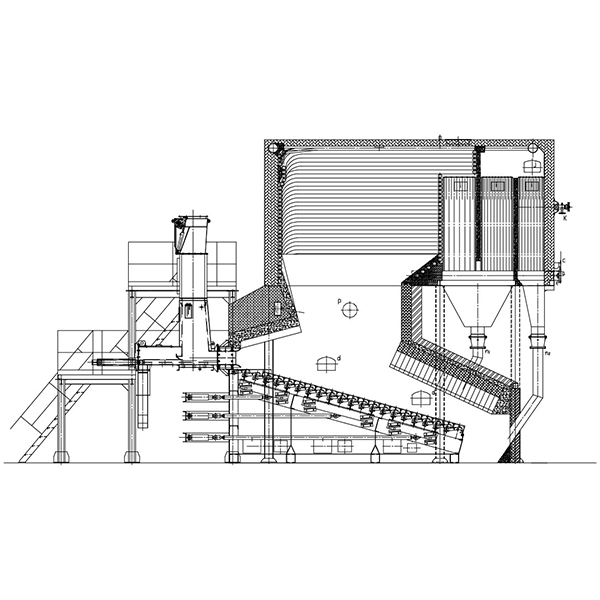

YLW series biomass fuel organic heat carrier furnace is an assembled forced circulation chain grate (reciprocating grate) boiler. The boiler consists of an upper body and a lower grate, which are assembled on site. The boiler has a compact structure, a small footprint, a high degree of assembly, a short installation cycle, and low installation costs.

The radiant heating surface of the boiler body adopts a single furnace or close-packed double-coiled coils, and the rear force serpentine convection heat exchange tube.

According to the fuel characteristics, a special anti-dusting structure is adopted to reduce the fouling and facilitate the cleaning. The convection heat exchange section of the boiler adopts high and low staggered rows, widening the spacing, and ash cleaning device to arrange the ash blowing device to reduce boiler ash accumulation and improve boiler efficiency.

Compared with the traditional coal-fired boiler, it has a larger furnace combustion space to adapt to the characteristics of high volatile content of biomass fuel.

The grate combustion chamber is heightened, and the secondary air is arranged: the grate is divided into the air inlet, the air volume is independently adjusted, and the grate is steplessly adjusted.

The grate adopts high temperature resistant material grate and reasonable air cooling form. The grate is reliable in use and has a long service life.

The feeding device has independent intellectual property rights and uses a material locking mechanism.

Furnace radiation heat exchange surface, convection heat exchange surface adopts special anti-wear structure.

The boiler adopts high-quality thermal insulation materials and special construction technology, and the thermal insulation effect is good.

The connection of the heating surface tube of the boiler requires full automatic gas shielded welding technology and equipment, which can be 100% real-time X-ray online detection. The welding quality is stable and reliable.

Performance advantage

1.High efficiency and energy saving

The furnace radiation heat exchange section adopts a double-dense coiled tube structure, and the convection heat exchange section has an S-type multiple return heat exchange.

The tail part is equipped with air preheater, steam waste heat boiler, hot water economizer for waste heat recovery according to the user's waste heat usage, reducing the exhaust temperature, improving boiler efficiency, reducing fuel consumption and saving energy.

The boiler adopts high-quality thermal insulation materials and special construction technology, with less heat loss, low exhaust temperature, and high boiler thermal efficiency.

The grate combustion chamber is heightened, and the secondary air for combustion is arranged. The fuel combustion is uniform and sufficient, and the combustion efficiency is high.

The special design of the grate and furnace arch, the grate is divided into the warehouse, the air volume is independently adjusted, and the fuel has wide adaptability.

The tail convection heat exchange section has a special structure and is equipped with a blowing device, which does not deposit ash during operation and has high heat exchange efficiency.

The heating surface is fully and reasonably arranged, the boiler starts up quickly and the load margin is large.

2.Safe and reliable

The radiant heating surface of the furnace is a close-packed coil, and the heating surface is adequately arranged, which effectively reduces the heat load on the surface of the tube, and the use of the heat transfer oil medium is safer.

The medium flow is reasonable. The heat transfer oil is low (inlet) to high (outlet). The medium gas generated during operation is difficult to stay in the furnace and can be easily discharged from the system.

The feeding device adopts a material locking mechanism to distribute the secondary air of the feeding material, which effectively prevents the flame from igniting and damaging the hopper.

The boiler operation adopts remote and near-ground monitoring, complete automatic control and monitoring instruments, safety, reliability and easy operation. Combining industrial automation control technology, Internet technology, computer software and artificial intelligence technology to build an industrial boiler IoT platform can achieve remote human-machine interaction and data sharing, and realize automatic control.

3.Environmental protection According to the requirements of the local bad warranty, the equipment with suitable flue gas treatment equipment shall be configured, and the flue gas emission shall meet the environmental protection requirements. .

Please fill in your procurement needs and contact information

+86-15969943322

+86-15969943322

Jasonqiao@xrdplymachine.com

Jasonqiao@xrdplymachine.com